About Textile Faculty

Textile Engineering is a profession that deals with the application of scientific and engineering principles to the design and control of all aspects of fibers, yarns, woven and knitted materials, technical textiles, nonwovens, products, and machinery. The Textile Faculty aims to work towards education and research excellence of that institution contributing to the goal of becoming an entrepreneurial university. In this regard, the faculty believes that the education and research excellence of the universities started by the institution and should play a greater role in producing citizens with knowledge, skills (soft and hard), attitudes, etc. The key task expected from technological institutions is to produce qualified professionals and transfer them to the industry and society.

Facility Manager for Textile Faculty Duties and Responsibilities

● Responsible for planning purchases of equipment, consumables, maintenance, and training services of the faculty laboratories of the EiTEX laboratories.

● Responsible for sustaining and maintaining the accredited faculty laboratories.

● Responsible for scope expansion of testing services of additional parameters.

● Responsible for communicating with the faculty dean, team leader, and analyst regarding testing services requests and laboratory administration issues.

● Responsible for verifying and approving test results and reports of the textile faculty laboratories.

● Responsible for assigning lab technicians who perform testing.

● Develop and maintain educational and research support technologies, software and online resources;

● Ensure the provision and functionality of classroom and syndicate rooms’ technologies and infrastructure.

● Ensure the provision and functionality of offices and syndicate rooms’ technologies, and infrastructure.

● Support and advise chairs in the development, maintenance, and access of their respective electronic, digital, and other online course system resources

● Oversee the demonstration and instruction of students in the preparation of materials and the use of laboratory and workshop equipment

● To ensure that the Technical team provides a helpful and timely reactive service to the requests of academic staff regarding preparation for laboratory practical sessions and research.

● To respond to student requests for assistance in practical sessions and where appropriate with projects and equipment support, where these needs cannot be met directly by a member of the Technical team, maintaining a professional approach to support students, promoting development, and preventing dependency.

● Oversee and contribute to the preparation and maintenance of equipment for laboratory work, including set up, dismantling, and resetting of experimental spaces as necessary.

● Provide timely, efficient, and customer-based printing and copying services

● Develop and produce audio-video resources: lectures, expert interviews, laboratory, experiments, conferences, historic places and events, and movies.

● Ensure a conducive environment for efficient laboratory and workshop utilization.

● Provide support and guidance on the use of materials and equipment for teaching and research.

● Make collaborative decisions with academic staff and the technical team regarding preparation for laboratory and workshop sessions.

● Provide advice to students and colleagues where necessary to allow them to make decisions concerning practical work.

● Initiate proposals and contribute to collaborative decisions with academic staff regarding, for example, the purchase of new capital equipment.

Textile Faculty Laboratories

Laboratories and Facilities of the Faculty

1.Laboratories under Textile Production

● Textile Production Research Lab I

● Textile Production Research Lab II

● Textile Production Fiber lab

● Textile Production Yarn lab

● Textile Production Fabric lab

● Textile Production knitting lab

● Textile Production Spinning lab

● Fabric Structure and Design lab

● Textile Workshop

● Selam Integrated Textile Teaching & Production Factory

List of advanced Instruments under Textile Production

Medical Textile Laboratory

2. Laboratories under Textile Chemistry

● Textile Chemistry Research lab I

● Textile Chemistry Research lab II

● Textile Wet processing lab

● Textile Chemistry fiber lab

● Textile Pretreatment lab

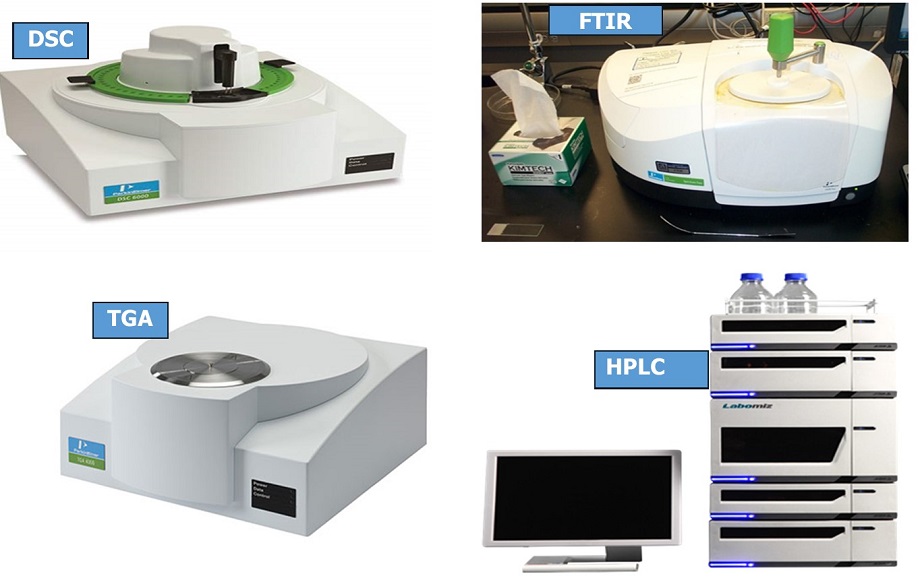

List of advanced Instruments under Textile Chemistry

Accredited Parameters

1. HVI within Seven (07) parameters

1.1 Mic,

1.2 UHML,

1.3 Strength (g/tex),

1.4 UI%,

1.5 Color Rd,

1.6 Color +b &

1.7 Trash area

2. Abrasion Resistance

3. Pilling Resistance

4. Air permeability

5. Fabric GSM

6. Fastness to Wash

7. Fastness to hot press

8. Qualitative Fiber Bled Analysis

Certificate

List of Laboratories under Textile Faculty-EiTEX

Laboratory/Workshop/ List (ዝርዝር) | location (የሚገኝበት) | Operational status (ያለበት ደረጃ) | Department (ት/ክፍል) | Institute |

Textile Production Research Lab I | Poly | Working | Textile Engineering | EiTEX |

Medical Textile Research Centre | Selam | Working | Textile Engineering | EiTEX |

Textile Production Research Lab II | Poly | Working (Accredited) | Textile Engineering | EiTEX |

Textile Chemistry Research Lab I | Selam | Working | Textile Chemical Process Engineering (TCPE) | EiTEX |

Textile Chemistry Research Lab II | Poly | Working (Accredited) | Textile Chemical Process Engineering (TCPE) | EiTEX |

Textile Wet processing lab | Poly | Working | Textile Chemical Process Engineering (TCPE) | EiTEX |

Textile Production fiber lab | Selam | Working | Textile Chemical Process Engineering (TCPE) | EiTEX |

Textile Chemistry fiber lab | Selam | Working | Textile Chemical Process Engineering (TCPE) | EiTEX |

Textile Production Yarn lab | Selam | Working | Textile Engineering | EiTEX |

Textile Production Fabric lab | Selam | Working | Textile Engineering | EiTEX |

Textile Production Knitting lab | Selam | Working | Textile Engineering | EiTEX |

Textile Production Spinning lab | Selam | Working | Textile Engineering | EiTEX |

Textile Pretreatment lab | Selam | Working | Textile Engineering | EiTEX |

Fabric Structure and Design lab | Selam | Working | Textile Engineering | EiTEX |

Textile Workshop | Poly | Working | Textile Engineering | EiTEX |

List of laboratories and parameters accredited under Textile Faculty -EiTEX

S/n. | Accredited lab | Parameters |

1 |

Textile Production Physical Lab | Abrasion Resistance ES ISO: 12947-2 |

2 | Pilling Resistance ES ISO: 12945-2 | |

3 | Air permeability ES ISO: 3792 | |

4 | Weight of Fabric ES ISO: 3801 | |

5 | Microniar: ASTM D5867 | |

6 | Strength (g/tex): ASTM D5867 | |

7 | UHML(mm): ASTM D5867 | |

8 | Uniformity Index (%): ASTM D5867 | |

9 | Color Rd: ASTM D5867 | |

10 | Color +b: ASTM D5867 | |

11 | Trash area (%): ASTM D5867 | |

12 | Textile Chemistry Lab | Fastness to Hot Press ES ISO: 105-X11 |

13 | Fastness to Washing ES ISO: 105-C10 | |

14 | Fiber Identification IS: 667 |

Service Offered by the Textile Faculty

1. Testing Services

● Physical, Mechanical, and Chemical properties of fibers

● Cotton fiber testing using HVI 1000 instrument

● Physical properties of yarn by USTER 5 instrument

● Physical, Mechanical, and Chemical properties of sliver

● Physical, Mechanical, and Chemical properties of yarn

● Physical, Mechanical, and Chemical properties of fabric

● Handling and Surface properties of fabric by KAWABATA instruments

● Fiber identification and testing

● Fiber structure analysis

● Polymer and fiber Characterization

● Color fastness and fading measurement

2. Processing Services

Bleaching, Dyeing, and Printing for different fabrics and garment products.

3. Products

Hand Woven Products which are used for different applications

Knitted Products which are used for different applications